Recent Posts

Categories

- Advanced Solutions (12)

- Archeology (7)

- Event Management Solutions (3)

- Events (18)

- Grocery E-commerce (18)

- Innovation (19)

- IT Services (14)

- Land Stewardship (10)

- Locker Solutions (19)

- Natural Resources (7)

- NOC Operations (12)

- Operations (10)

- Science Projects (10)

- Security (8)

- Smart Retail (20)

- Supply Chain (12)

Paper: Integrating Industrial PLC Equipment with Higher Level Software

- Feb. 2, 2014

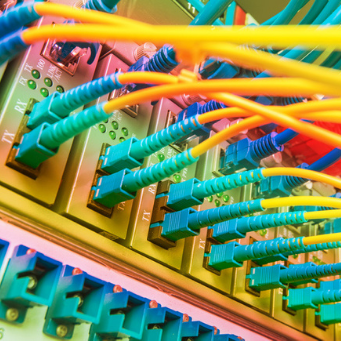

Connecting Systems Together

For over 15 years I have worked on building large distributed control systems that integrate custom applications, industrial control platforms and intelligent network devices into large distributed control systems. In some we integrated these control and data acquisition system with large enterprise grade databases. Today there are a lot of organisations talking about the “Internet of Things” and how to do this on a larger scale.

In reality this involves careful consideration of security issues, network architectures and in many cases development of custom software that provides semantic meaning to the data at that interface point.

Security

The first key challenge to address is that many of these devices were never intended to be integrated into larger networks and therefore do not appropriate safeguards in place to be exposed on either a corporate network or a public network. Great care is required to ensure that these devices are appropriately protected.

Network Architecture

The network architecture must take into account the need to segregate these devices while still having drives that map and provide meaning for the data from the lower level device into a higher level system. That higher level system could be a data acquisition system, a quality assurance management database, an ERP system or other corporate databases. Regardless semantic and temporal meaning needs to be added to the data as it moves from that device control layer into the higher enterprise layer in the system.

This coupled with security considerations makes this layer software a critical interface point. We sometimes call these drivers, however they are play a much more important role in providing that mapping.

A good example is the driver described in the following paper that is used to interface Siemens S7/300 and S7/400 PLC equipment with EPICS database records:

Outcome

Why do this? What value are these connections?

Given the effort involved these are valid questions to ask. The reality is increasing decisions are being made based on holistic integrated view of how multiple systems are functioning getting all of the data from multiple devices into a single system permits the generation of a unified view of what is happening. It provides the insight needed to make the correct tactical decision now.

When coupled with historical data it supports that analysis of long-term trends and to make informed strategic decision.